wholesale antisnoring nasal strips factory

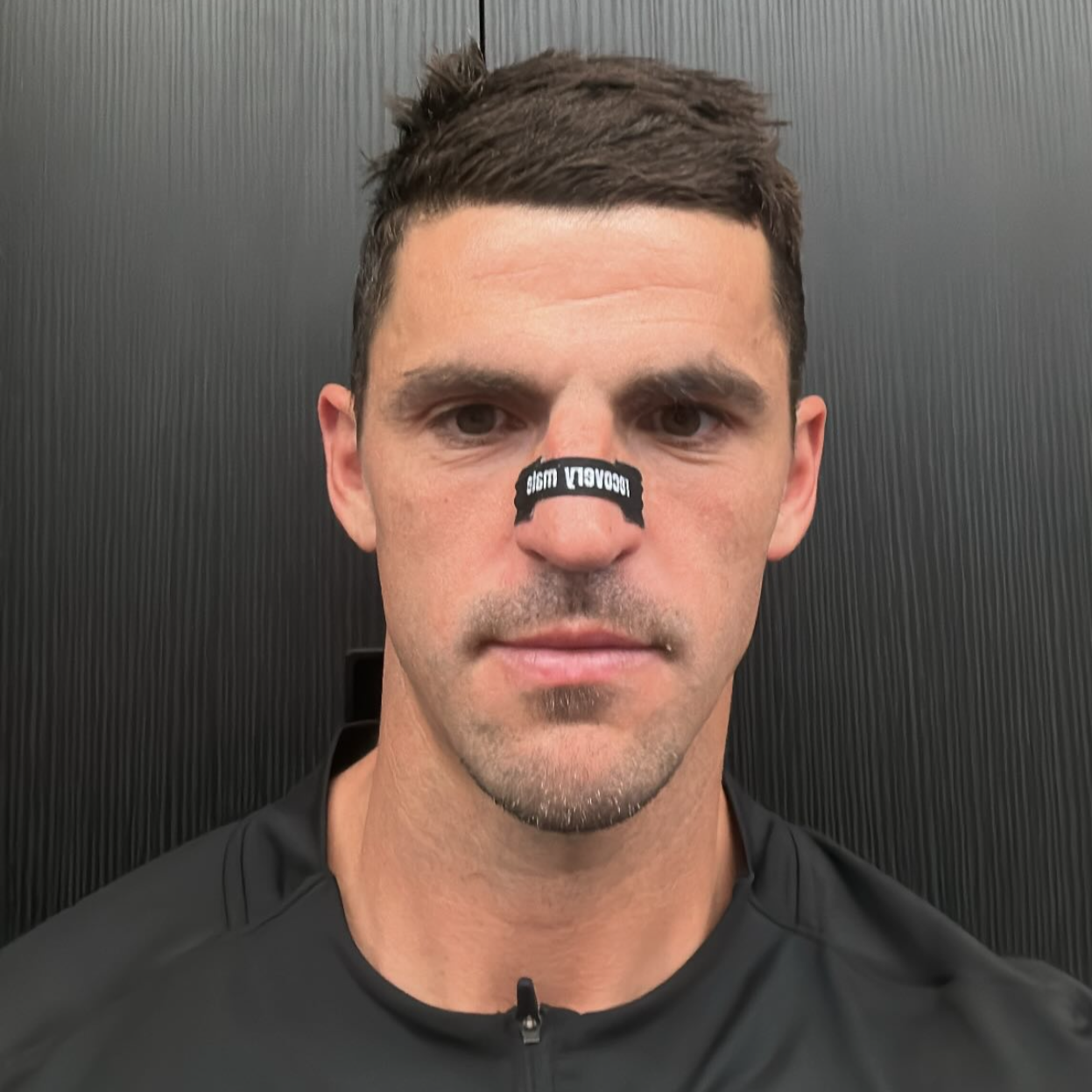

A wholesale antisnoring nasal strips factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality nasal strips that effectively combat snoring issues. The facility employs advanced manufacturing processes and automated production lines to ensure consistent quality and high output capacity. These factories utilize medical-grade materials, including hypoallergenic adhesives and flexible spring-like bands, to create nasal strips that gently open nasal passages during sleep. The production process incorporates rigorous quality control measures, from raw material inspection to final product testing, ensuring each strip meets international safety and effectiveness standards. The factory's capabilities typically include custom design options, allowing for various sizes and shapes to accommodate different nose bridges and facial contours. Modern packaging facilities within the factory enable bulk packaging solutions while maintaining product integrity. The facility also maintains clean room environments for certain production phases, ensuring optimal hygiene standards. With research and development departments on-site, these factories continuously work on improving strip design and adhesive technology for enhanced comfort and effectiveness. The integration of automated quality inspection systems using computer vision technology helps maintain consistent product quality while maximizing production efficiency.