best breathing strips factory

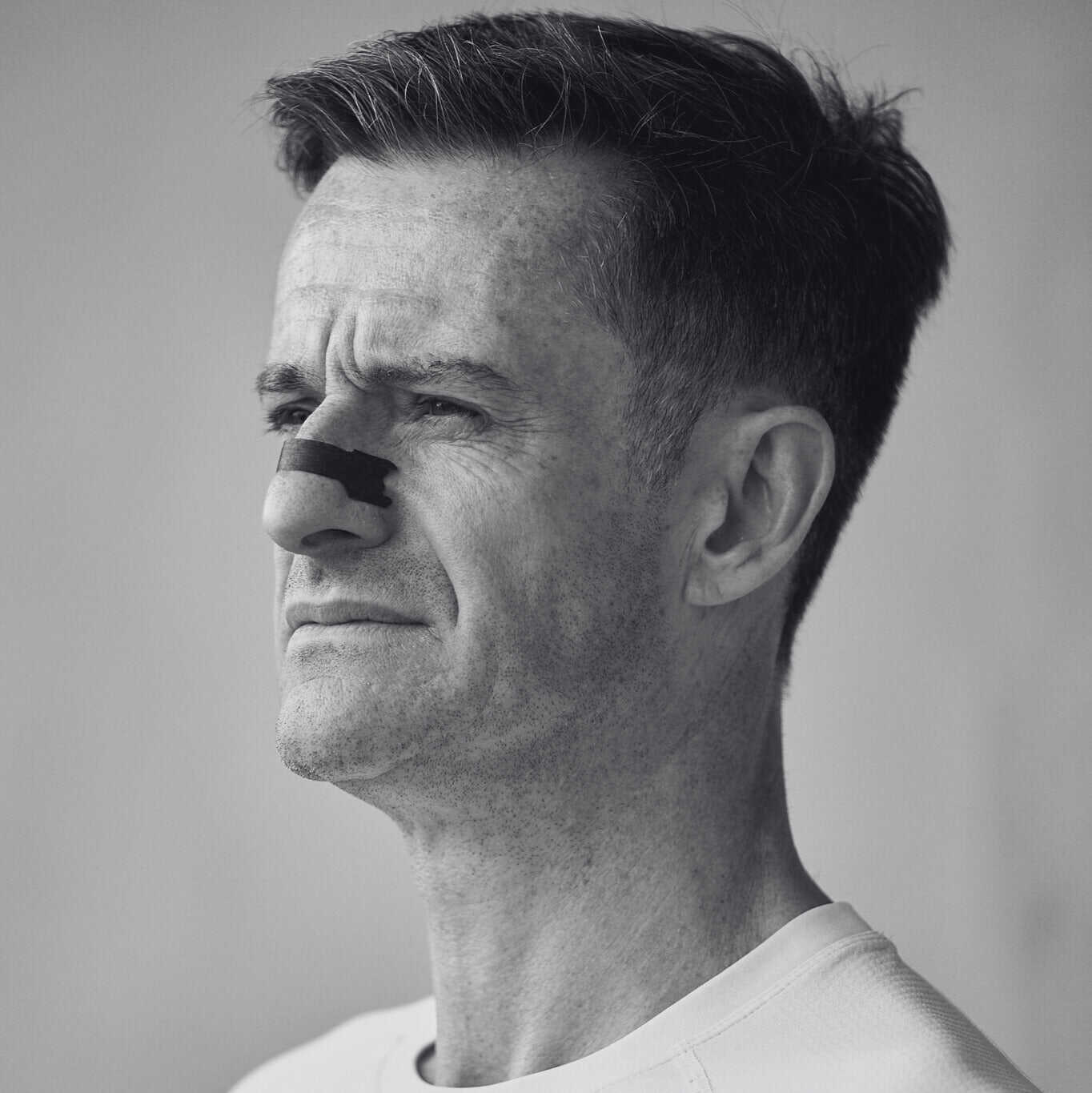

Our state-of-the-art breathing strips factory represents the pinnacle of modern manufacturing excellence in respiratory aid production. The facility spans 50,000 square feet of pristinely maintained production space, equipped with advanced automation systems and clean room technology that maintains ISO Class 7 standards. The factory implements a sophisticated multi-layer production process, utilizing medical-grade polymers and hypoallergenic adhesives to create breathable, comfortable nasal strips. Our production lines operate 24/7 with real-time quality monitoring systems that ensure each strip meets stringent quality standards. The facility features specialized die-cutting equipment that achieves precise dimensions and smooth edges for optimal comfort. Advanced coating systems apply the pressure-sensitive adhesive uniformly, while our proprietary spring-like bands are engineered to provide optimal nasal passage dilation. The factory's testing laboratory conducts continuous quality assurance checks, including adhesive strength testing, materials analysis, and durability assessments. With an annual production capacity of over 100 million strips, our factory maintains consistent supply while adhering to FDA regulations and international quality standards.